In today’s world, where sustainability and environmental consciousness are at the forefront of industrial innovation, the paper egg tray machine has emerged as a game-changer in the packaging industry. This machine is designed to produce egg trays and other molded pulp products using recycled paper, offering an eco-friendly and cost-effective alternative to plastic and foam packaging. This article delves into the workings of the paper egg tray machine, its benefits, and its role in promoting sustainable packaging solutions.

What is a Paper Egg Tray Machine?

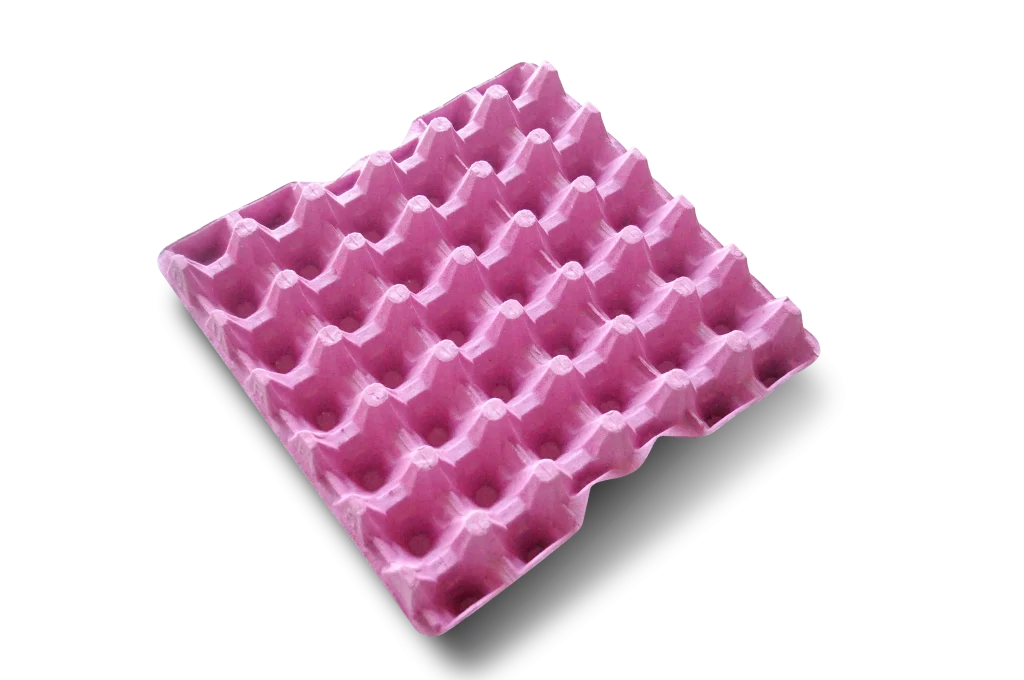

A paper egg tray machine is a specialized piece of equipment that transforms waste paper into molded pulp products, primarily egg trays. The process involves recycling paper waste, such as newspapers, cardboard, and magazines, into a pulp mixture, which is then molded and dried to create sturdy, biodegradable trays. These trays are widely used in the poultry industry to safely transport and store eggs, reducing breakage and ensuring product quality.

The machine is highly versatile and can also produce other molded pulp products, such as fruit trays, coffee cup holders, and packaging for electronics, making it a valuable asset for businesses looking to adopt sustainable practices.

How Does a Paper Egg Tray Machine Work?

The operation of a paper egg tray machine can be broken down into four main stages:

-

Pulping:

Waste paper is mixed with water in a hydrapulper to create a uniform pulp mixture. The hydrapulper shreds the paper and blends it with water to form a slurry, which is then stored in a pulp tank. -

Molding:

The pulp slurry is transferred to the molding system, where it is poured into specially designed molds. A vacuum system removes excess water, leaving behind the formed trays. The molds can be customized to produce different shapes and sizes, depending on the product requirements. -

Drying:

The molded trays are then dried to remove any remaining moisture. There are three primary drying methods:-

Natural Drying: Trays are dried under the sun. This method is cost-effective but time-consuming.

-

Brick Drying: Trays are dried in a brick drying line, which uses heat generated by a furnace. This method is faster than natural drying.

-

Metal Drying: Trays are dried in a metal drying line, which is the most efficient and suitable for large-scale production.

-

-

Packing:

Once dried, the trays are stacked and packed for delivery. Advanced machines may include automatic stacking and packing systems to streamline this process.

Benefits of Using a Paper Egg Tray Machine

-

Eco-Friendly:

The machine uses recycled paper as its primary raw material, reducing waste and promoting sustainability. The end products are biodegradable and compostable, making them an environmentally friendly alternative to plastic and foam packaging. -

Cost-Effective:

The raw materials are inexpensive and readily available, making the production process highly cost-effective. Additionally, the machine’s efficiency and low operational costs contribute to a high return on investment. -

Versatility:

With customizable molds, the machine can produce a wide range of molded pulp products, catering to various industries beyond the poultry sector. -

Durability:

Paper egg trays are lightweight yet durable, providing excellent protection for fragile items like eggs and fruits during transportation and storage. -

Scalability:

The machine is available in different models, from small manual units to large fully automatic systems, allowing businesses to scale their production according to demand.

Applications of Paper Egg Trays

While egg trays are the primary product, the machine’s versatility allows for the production of other molded pulp items, including:

-

Fruit and vegetable trays

-

Coffee cup holders

-

Electronic packaging

-

Seedling trays

-

Bottle and can holders

This adaptability makes the paper egg tray machine a valuable investment for businesses in various sectors.

Building a Paper Egg Tray Production Line

Setting up a paper egg tray production line involves several key steps:

-

Market Research:

Analyze the demand for egg trays and other molded pulp products in your target market. Identify potential customers and competitors. -

Machine Selection:

Choose a machine that aligns with your production goals and budget. Consider factors such as production capacity, automation level, and drying method. -

Raw Material Sourcing:

Establish a reliable supply chain for waste paper. Ensure the paper is clean and free from contaminants to maintain product quality. -

Production Setup:

Install the machine and set up the production line, including the pulping, molding, drying, and packing sections. Ensure proper ventilation and space for drying. -

Quality Control:

Implement quality control measures to ensure the trays meet industry standards. Regularly inspect the trays for strength, durability, and uniformity. -

Marketing and Sales:

Develop a marketing strategy to promote your products. Highlight the eco-friendly and cost-effective nature of your trays to attract customers.

Challenges and Solutions

-

Initial Investment:

The upfront cost of the machine can be high. To mitigate this, start with a smaller, semi-automatic model and upgrade as your business grows. -

Maintenance:

Regular maintenance is essential to keep the machine running smoothly. Schedule routine inspections and repairs to avoid downtime. -

Drying Efficiency:

Drying can be a bottleneck in the production process. Invest in an efficient drying system, such as a metal drying line, to improve productivity.

Conclusion

The paper egg tray machine is more than just a piece of equipment—it’s a sustainable solution for modern packaging needs. By converting waste paper into functional, eco-friendly products, this machine not only benefits businesses but also contributes to environmental conservation. Whether you’re a small entrepreneur or a large-scale manufacturer, investing in a paper egg tray machine is a step toward a greener, more sustainable future. With its versatility, cost-effectiveness, and environmental benefits, this machine is truly a game-changer in the packaging industry.