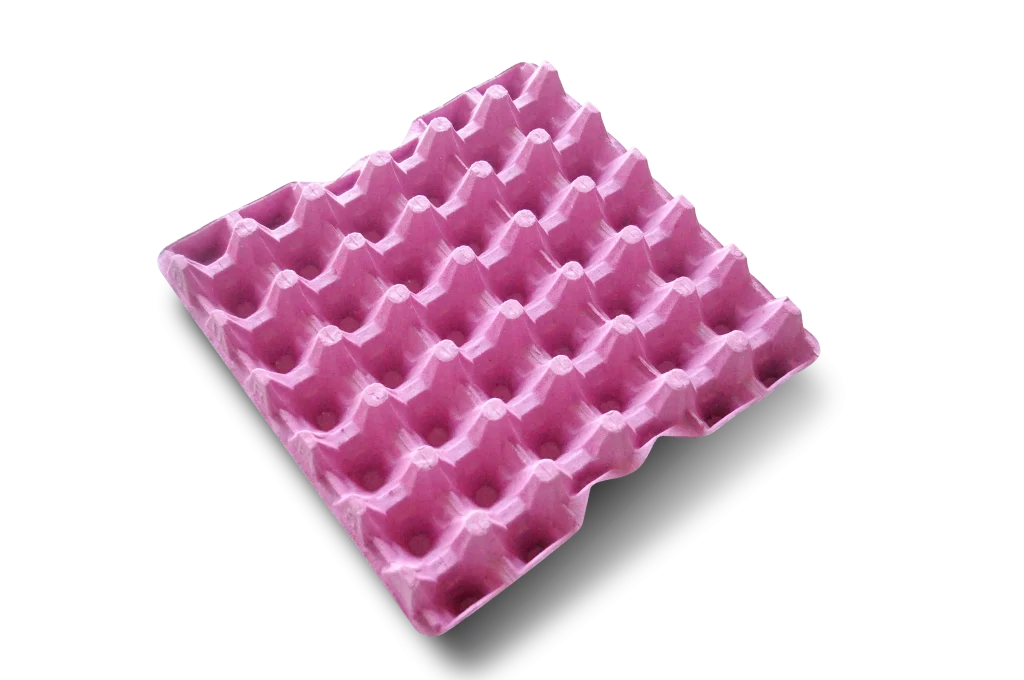

The egg tray manufacturing industry plays a pivotal role in the packaging sector, primarily catering to the needs of the poultry market. Given the increasing global demand for eggs, the necessity for efficient and protective packaging solutions has amplified. Egg trays are specifically designed to secure eggs during transportation and storage, preventing damage and ensuring product quality. Their design minimizes movement and maximizes airflow, which is crucial for maintaining freshness, thus driving their popularity in the poultry industry.

Materials used in egg tray production include recycled paper, plastic, and foam. Recycled paper pulp is the most common material due to its environmental benefits and cost-effectiveness. The use of sustainable materials not only reduces the ecological footprint of the manufacturing process but also aligns with the growing consumer preference for eco-friendly products. In recent years, the industry has observed a shift towards biodegradable and recyclable options, reflecting the increasing importance of sustainability in manufacturing practices.

The role of manufacturers in the egg tray business cannot be overstated. They are responsible for producing high-quality products that meet the stringent standards set by poultry producers. The ability to adapt to changing market trends and consumer expectations is critical for manufacturers aiming to maintain a competitive edge. Embracing advancements in production technology, such as automated machinery and innovative designs, can help enhance efficiency and improve the overall quality of egg trays.

Looking towards the future, the growth prospects of the egg tray business appear promising. With rising concerns over food safety and the heightened emphasis on sustainable packaging solutions, the demand for egg trays is expected to increase. Furthermore, as the poultry industry continues to expand globally, the necessity for effective packaging solutions will remain a priority. Therefore, manufacturers who prioritize sustainability and adaptability will likely thrive in this evolving landscape.

Understanding the Egg Tray Making Process

The egg tray making process begins with the collection of raw materials, primarily paper waste, and other cellulose-based materials. These materials are gathered from various sources, such as newspapers, cardboard, and cartons. Proper segregation of high-quality raw materials is crucial, as it directly affects the texture and strength of the final egg trays. After gathering, the materials are shredded into smaller pieces to facilitate better pulping.

Next, the shredded materials undergo a pulping process, where they are mixed with water to create a slurry. This slurry is then subjected to vigorous agitation, breaking down the fibers and creating a homogenous pulp mixture. Pulp molding is a key technique in the egg tray production process; it involves using specialized molds to shape the pulp into egg trays. The machine used for this purpose can efficiently produce multiple trays simultaneously, enhancing the manufacturing speed.

Once the pulp has been molded into the desired shape, the trays must undergo a drying process to remove excess moisture. This is conducted in two stages: pre-drying, where the trays are air-dried, and the subsequent drying in an industrial dryer. Proper drying is essential, as it determines the structural integrity and resistance of the trays. Once dried, the egg trays are inspected for quality assurance to ensure they meet the required standards.

The final stage in the egg tray making process involves finishing touches, which may include surface treatment for increased durability and packaging for distribution. Companies often use biodegradable coatings to enhance moisture resistance and protect the trays during transport. This meticulous approach to the production process not only ensures high-quality products but also promotes environmental sustainability by utilizing recycled materials. Overall, the egg tray making process is an intricate sequence of steps that transforms raw materials into functional packaging solutions for the egg industry.

HGHY EGG TRAY MACHINE

Egg Crate Making Machines: Types and Features

Egg crate making machines are essential in the production of egg trays, serving as the backbone of an efficient manufacturing process. These machines come in various types, each designed to cater to different production needs and capacities. The primary categories include manual, semi-automated, and fully automated machines. Manual machines require significant human intervention, making them ideal for small-scale operations. In contrast, semi-automated machines streamline production, allowing for a balance between labor and automation. Fully automated machines, however, are the most advanced and suitable for large-scale operations, capable of producing thousands of egg trays in a short time frame.

Key features of egg crate making machines vary according to their level of automation and production capacity. Essential functionalities include pulp forming, drying, and packaging. Pulp forming machines utilize recycled paper and water to create the egg trays, followed by drying systems that facilitate rapid moisture removal, ensuring durability. Moreover, some modern machines offer integrated packaging solutions to further enhance efficiency. Each machine’s operational speed, power consumption, and maintenance requirements are critical factors for manufacturers to consider when selecting the right model.

Technological advancements have significantly impacted egg crate making machines, leading to increased efficiency and enhanced production capacity. Innovations, such as automated feeding systems and enhanced drying technologies, contribute to minimizing energy costs and optimizing workflow. Furthermore, leading brands in the market, such as Liyang Machinery and Dazhang Group, offer various models with unique features tailored to specific industry demands. When choosing an egg crate making machine, businesses should assess factors like production scale, budget, and desired automation level, ensuring they select a machine that aligns with their operational goals while maximizing output and minimizing downtime.

Starting Your Own Egg Tray Business

Embarking on the journey to establish an egg tray business involves several critical steps that require thorough planning and execution. The first step entails conducting comprehensive market research. Understanding the current trends, consumer preferences, and the competitive landscape can provide valuable insights for potential business owners. Identifying your target market, whether it involves local farms, grocery stores, or wholesalers, will help tailor your offerings effectively.

Next, sourcing the right raw materials is crucial for manufacturing high-quality egg trays. Common materials include recycled paper, which is not only cost-effective but also promotes sustainability. Establishing reliable relationships with suppliers ensures that you have a consistent and quality supply of materials, which is essential for meeting production demands.

Selecting appropriate machinery is another significant aspect of starting your egg tray business. Depending on production volume and budget, you may choose from manual or fully automatic machines. Each option presents different advantages, including costs, efficiency, and labor requirements. Evaluating your needs and resources will guide your decision-making process.

Creating a well-structured business plan is pivotal for articulating your business strategy, financial projections, and operational framework. A thorough business plan will aid in identifying your unique selling proposition and can attract potential investors or financial institutions to support your venture. Furthermore, exploring various financing options, such as small business loans or grants, is essential to secure the necessary capital for startup costs and ongoing expenses.

Lastly, successful marketing strategies are vital for promoting your egg tray business and establishing a solid customer base. Utilizing digital marketing, attending trade shows, and building relationships with local businesses can effectively increase visibility and sales. By implementing these strategies, you can carve out a niche in the competitive packaging market, ultimately leading to sustainable growth and profitability in your egg tray business.