The production of paper egg trays is a multifaceted process that entails several notable steps, each crucial to the overall quality of the final product. Initially, the sourcing of raw materials is fundamental, predominantly involving recycled paper and cardboard. This eco-friendly approach not only reduces waste but also mitigates environmental impact, aligning with sustainable practices in modern manufacturing.

Following raw material acquisition, the pulping process begins. This stage involves breaking down the collected paper products into a slurry, which is subsequently processed to remove contaminants and achieve the desired consistency. The quality of the pulp directly influences the strength and durability of the resultant egg trays, emphasizing the importance of this step. Here, advancements in technology play a pivotal role, with new pulping techniques allowing for more efficient processing and better material quality.

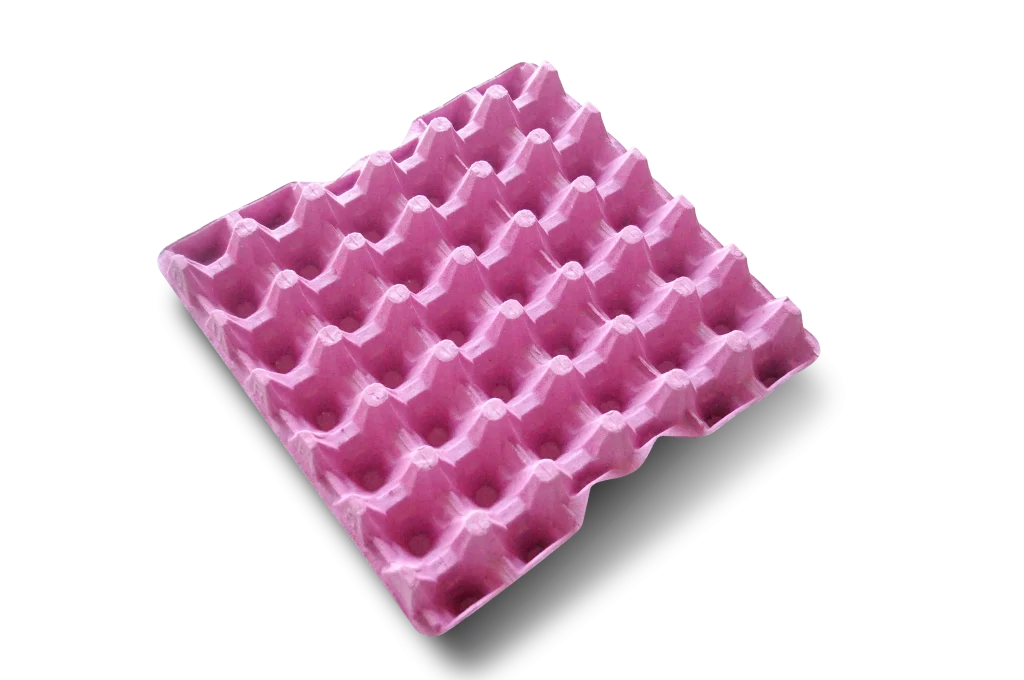

Once the pulp is prepared, the next critical phase is mold design. The molds shape the pulp into the egg tray format, and their design can significantly affect the tray’s functionality and stacking ability. Precision in mold craftsmanship ensures that the trays fit standard egg carton sizes, thereby facilitating ease of use in the packaging and transportation of eggs. Innovations in mold technology have further enhanced replication accuracy, ensuring consistent product quality.

Finally, the drying stage is essential for removing excess moisture from the formed trays, allowing them to achieve a robust structure. Various drying techniques, such as natural sun drying or utilizing industrial drying machines, are employed based on production capacity and environmental conditions. The selection of machinery in this phase influences the overall efficiency and scalability of the production process. Equipment that enhances the drying rate can significantly increase output while maintaining high standards of product quality.

Economic Benefits of Paper Egg Tray Manufacturing

The production of paper egg trays presents numerous economic benefits that can be analyzed from various angles. Firstly, the cost analysis of establishing a manufacturing operation reveals a relatively low initial investment when compared to other production processes in the packaging industry. Equipment costs for paper egg tray production are manageable, especially when considering the availability of second-hand machinery. Furthermore, sourcing raw materials primarily from recycled paper reduces material costs significantly, allowing manufacturers to operate with a lower overhead while maintaining competitiveness.

As businesses begin their foray into paper egg tray manufacturing, they can anticipate substantial potential profits. The market demand for sustainable packaging solutions has consistently grown, driven by heightened environmental awareness. Producers can capitalize on this trend by supplying to different sectors, including agriculture, food service, and retail, which increasingly prefer recyclable and biodegradable options. The financial returns from entering this market can be bolstered as businesses prioritize lower material costs and increase production efficiency over time.

Another critical economic advantage of this industry is its contribution to job creation. As new manufacturing facilities open, they not only provide employment opportunities within the production stages but also stimulate ancillary services such as transportation and distribution. This growth helps strengthen local economies, creating a ripple effect that fosters the development of small businesses and stimulates entrepreneurship within communities.

Moreover, leveraging recycled materials for production carries environmental benefits that further enhance economic impact. Utilizing waste paper not only helps reduce landfill waste but also lowers the carbon footprint associated with sourcing virgin materials. Successful case studies, such as those from established companies, showcase how this eco-friendly approach can attract more customers and elevate brand loyalty, leading to a positive economic cycle for both businesses and communities.

The Industrial Chain and Market Dynamics

The industrial chain of paper egg tray production encompasses several key players, each integral to ensuring a streamlined operation from raw material sourcing to end-consumer delivery. At the outset, suppliers provide essential materials, primarily recycled paper, which serves as the foundational component in the fabrication of paper egg trays. These suppliers are often responsible for maintaining sustainable sourcing practices, which not only meet industry standards but also cater to the growing consumer demand for environmentally friendly products.

Manufacturers play a pivotal role in this chain, wherein they transform raw materials into finished products through various processes including pulp preparation, molding, drying, and packaging. Innovations in machinery and production techniques are crucial here, enabling manufacturers to enhance efficiency, reduce waste, and lower production costs, thereby improving their competitive edge in the marketplace.

Following production, distributors take the helm in delivering these products to retailers or end-users. Their function involves strategic logistics management, as they must ensure timely and safe transportation of paper egg trays while navigating challenges such as fluctuating fuel prices and supply chain disruptions. Retailers, in turn, are responsible for presenting these products to consumers, highlighting the benefits of using paper egg trays, which are often preferred due to their biodegradable characteristics and strength.

The demand for paper egg trays is influenced by various factors, including growing environmental concerns and the increasing shift towards sustainable packaging solutions in the food sector. Consumer preferences often lean towards biodegradable and recyclable options, propelling the market for paper egg trays forward. Additionally, global trends, such as the rise of organic farming and the need for eco-friendly solutions, significantly impact local producers, driving them to adapt and innovate continuously. The competitive landscape must not be overlooked, as it fosters innovation, compelling manufacturers to enhance product quality and diversify available offerings in response to market needs.

Sustainability in Paper Egg Tray Production

The production of paper egg trays is increasingly subject to scrutiny concerning its environmental impact. As consumer awareness regarding sustainability grows, manufacturers within the egg tray industry are adopting greener practices to align with changing consumer preferences. This shift is not only beneficial for the environment but also represents a strategic move to attract consumers who prioritize ecological considerations when making purchasing decisions.

One significant trend is the use of recycled materials in the manufacturing process. Companies are increasingly sourcing post-consumer waste paper as a primary raw material for egg tray production. This practice reduces the carbon footprint associated with raw material extraction and contributes to waste minimization. Innovations such as utilizing agricultural waste—like sugarcane bagasse or wheat straw—are also emerging, thus further diversifying the sustainable materials available. The transition to these eco-friendly alternatives significantly mitigates the negative impacts usually linked to traditional production methods.

Moreover, advancements in manufacturing technology promise to enhance efficiency while reducing waste. The implementation of automation and precision technology ensures that production processes are optimized, contributing to lower energy consumption. By adopting technologically advanced machinery, manufacturers can achieve a more streamlined workflow, which not only cuts down production costs but also aligns with the industry’s sustainability goals.

Looking to the future, the regulatory landscape will likely evolve to prioritize sustainability even further. Potential legislation aimed at reducing environmental impacts in manufacturing could impose stricter guidelines, encouraging businesses to adopt more sustainable practices. As consumer expectations continue to influence the market, it is anticipated that companies that invest in sustainable egg tray solutions will thrive while those resistant to change may face declining market viability.

HGHY EGG TRAY MACHINE

The Hot Press Egg Crate Making Machine is specifically designed for the efficient mass production of egg cartons and related packaging products. It is capable of producing a comprehensive range of items that are essential for the safe packaging and transportation of eggs, such as egg cartons, egg boxes, cup holders, small baskets, and bottle trays, all of which require hot pressing after drying. The machine excels in manufacturing these products, ensuring high efficiency and precision to meet various packaging needs.