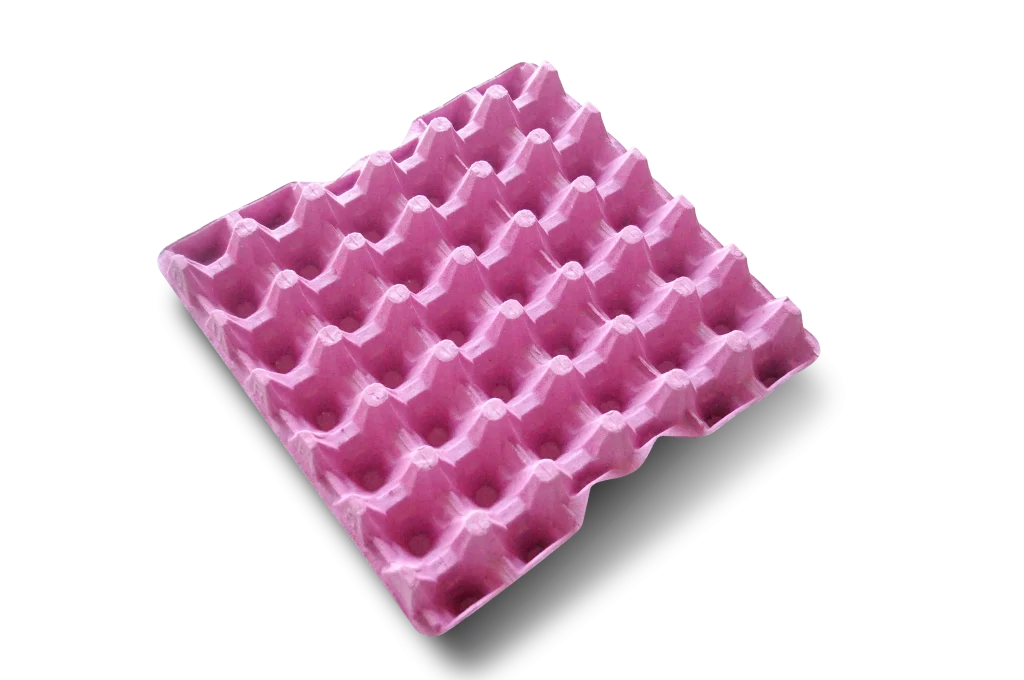

Egg trays are an essential component in the transportation and storage of eggs, serving the critical purpose of protecting these fragile products from damage. The egg tray production process involves creating a packaging solution that is both durable and efficient, catering to the needs of the agricultural sector. The trays are designed to hold eggs securely, minimizing movement and providing cushioning during handling and transit. This is particularly important in commercial egg production, where maintaining product quality is paramount.

The production of egg trays has gained significance in the packaging industry, emphasizing sustainability and cost-effectiveness. Various materials are employed in the manufacturing of egg trays, including molded pulp, plastic, and foam. Molded pulp egg trays, made from recycled paper products, have surged in popularity due to their environmentally friendly attributes. These trays not only protect eggs but are also biodegradable, aligning with the increasing demand for sustainable packaging solutions in various sectors.

Furthermore, the choice of materials significantly influences the overall effectiveness of egg trays. In addition to providing adequate protection, the materials used must also be lightweight and easy to stack, facilitating efficient storage and transport. The egg tray production process is often driven by the need to strike a balance between functionality and environmental responsibility. Thus, manufacturers continually explore innovative approaches that enhance the robustness of egg trays while minimizing their ecological footprint. As the agricultural and packaging industries evolve, understanding these dynamics is vital for stakeholders aiming to optimize their operations while meeting sustainability goals.

Paper Pulp: The Most Common Material

Paper pulp stands out as one of the most prevalent materials used in the production of egg trays. This material is derived primarily from recycled paper products, which undergo both mechanical and chemical processes to be transformed into a usable pulp. The advent of sustainable practices has elevated paper pulp to a favored choice within the industry, especially given its environmental benefits and cost-effectiveness.

The process of converting recycled paper into paper pulp begins with the collection of waste paper, which is subsequently cleaned and shredded. This shredded paper is then subjected to mechanical agitation, often in the presence of water, which helps separate the fibers. In many cases, a chemical treatment follows to further disintegrate the ligaments that bind the paper, resulting in a fibrous slurry known as paper pulp. The versatility of paper pulp in egg tray production lies not only in its adaptability but also in the ease of sourcing, considering the abundance of recycled paper materials available.

Moreover, employing paper pulp for egg trays aligns with contemporary sustainability goals. The biodegradability of paper products ensures that the post-consumer waste does not contribute significantly to environmental pollution. Another notable advantage of using paper pulp is its cost-effectiveness. The low processing costs associated with recycled materials enable manufacturers to provide products at competitive prices in the market while maintaining quality standards.

The production process of egg trays from paper pulp generally involves molding and drying stages. The liquid pulp is placed in molds that shape it into trays, followed by a drying process to eliminate moisture content, solidifying the structure. The quality of the paper utilized in the initial stages directly influences the integrity and durability of the final product. Consequently, monitoring and managing paper quality is vital to ensuring that the egg trays meet performance and safety requirements.

HGHY EGG TRAY MACHINE

The egg tray machine is the most important equipment in the egg tray production line. If you are struggling with how to deal with a large number of discarded cartons, magazines, papers, and old books, and wondering how to turn waste into treasure, the pulp egg tray production line is a great solution for you.

Plastic Egg Trays: Durability and Reusability

Plastic egg trays have become increasingly popular in the egg production industry due to their remarkable durability and reusability. Unlike traditional materials such as cardboard or foam, plastic offers superior resistance to moisture and physical stress, ensuring that eggs are well-protected during handling and transportation. This inherent strength contributes to a longer lifespan for plastic trays, making them a cost-effective solution for egg producers.

The most commonly used plastics in egg tray production are polyethylene terephthalate (PET) and high-density polyethylene (HDPE). PET is renowned for its excellent clarity and resilience, while HDPE is valued for its toughness and resistance to impact. Both materials not only provide robust protection for eggs but also allow for transparency, enabling easy monitoring of the contents without opening the tray. Additionally, these plastics are lightweight, which aids in reducing transportation costs.

One of the significant advantages of using plastic egg trays is their ability to be reused multiple times, which is a substantial benefit in a world increasingly focused on sustainability. Producers can effectively wash and sanitize plastic trays, allowing them to maintain hygiene standards while minimizing waste. However, environmental impact concerns often arise regarding plastic use. It is important to note that many plastic egg trays are recyclable, contributing to a circular economy where materials are repurposed instead of ending up in landfills.

The manufacturing process for plastic egg trays typically involves injection molding or thermoforming techniques, which shape the plastic into the desired tray form while considering the necessary design elements for optimum egg protection. This includes creating individual compartments designed to cradle each egg securely, preventing damage during transit. Overall, the adoption of plastic egg trays emphasizes both performance and sustainability in the egg production industry.

Innovative Materials in Egg Tray Production

The egg tray production industry has seen significant advancements in recent years, particularly with the introduction of innovative materials aimed at making the process more sustainable. Traditional materials used in egg tray manufacturing, such as recycled paper and cardboard, are now being supplemented by alternatives like biodegradable plastics. These bioplastics, derived from renewable sources such as cornstarch, showcase an impressive capability to decompose naturally, thus minimizing environmental impact while maintaining functionality. As the industry seeks ways to reduce its carbon footprint, the appeal of biodegradable options continues to rise.

Another promising alternative gaining traction is eco-friendly composites, which combine multiple materials to leverage their beneficial properties. These composites often integrate natural fibers, such as those obtained from sugarcane pulp or bamboo. Both materials are not only lightweight and durable but also add a level of renewability that traditional materials lack. Additionally, bamboo, being one of the fastest-growing plants, provides a sustainable harvesting option, further enhancing its appeal for use in egg trays.

Despite the numerous advantages these innovative materials offer, several challenges must be addressed. One significant obstacle is the production cost associated with these advanced materials. Investments are required in research and development to optimize production techniques, which, in turn, can increase the overall expense for manufacturers. Moreover, scaling these materials for widespread use poses its own set of complexities, as manufacturers must seek effective methods to ensure consistent quality and supply.

Future trends in material engineering are expected to focus on overcoming these barriers, with ongoing research into improving the efficiency of production processes and reducing costs. As consumer demand for sustainable products continues to grow, the egg tray production industry stands poised to embrace these innovative materials, ultimately leading to greener solutions in packing and distribution.